Universal Modular Test Bench

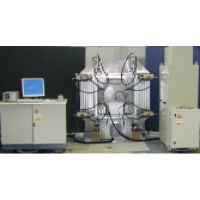

This type of very ductile Test Bench was designed and developed by our Ing. Brivio and is actually present in numerous test laboratories that have adopted it. It allows for several independent tests on the same bench, using a single Workstation, and to create trial configurations of considerable complexity.

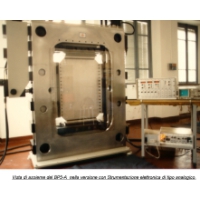

In essence, the Bench is a very solid base in welded steel, with machined surfaces of centesimal precision and internal reinforcements at various levels to provide the structural strength. Externally, it is worked with orthogonal guides on 5 faces. For the basic format, the external dimensions are: 750 x 1500 H 700 mm, and c.a. 3 Ton of weight.

In addition to the accessories which are from time to time offered to the Customer for the specific needs, the grooved guides allow for a fast and easy configuration, as well as the precise positioning of the various components.

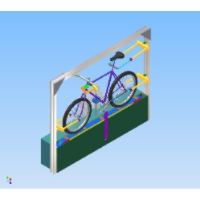

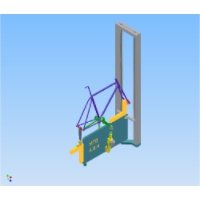

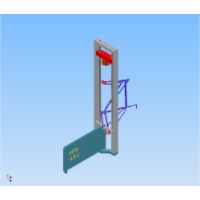

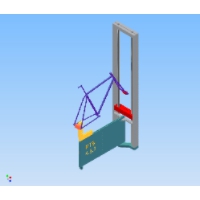

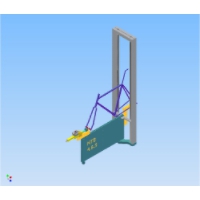

The photos below show examples of Bench configurations, on which various equipments are installed obtaining mono or multi-axial Test Benches. As you can see, adding just a few simple connections to the specimen and Servo Actuator/s this Bench can become, for example:

- a Flexural Test Bench for MTB forks

- a Column Test Bench for Fatigue Tests on components

- a Torsional Test Bench

This type of Modular Test Bench has already been used in many applications with considerable advantages both for the technical content, and for the limited time required to setup very complex configurations.

Being a self-supporting structure positioned on anti-vibrations, it can move and install in a simple and versatile way.